Dairy farming, a pivotal branch of the vast agricultural field, provides a myriad of products that form the cornerstone of human nutrition worldwide. This dynamic industry, steeped in tradition yet continually innovating, relies heavily on an indispensable piece of machinery – the cream separator. Without the influence of this transformative technology, dairy farming as we know it would be an entirely different landscape.

Cream separators have played a game-changing role in the dairy farming sector, streamlining the process of cream extraction and making it more efficient and scalable. From small-scale operations to industrial dairy farms, these machines have profoundly impacted the ability of farmers to produce high-quality, consistent dairy products.

What is a Cream Separator?

A cream separator is essentially a device that makes the complex science of cream separation remarkably straightforward for the end user. Fundamentally, it splits the milk into two major components: cream and skimmed milk. This function might sound complex when considering the science that enables it. Centrifugal force, differing densities, and carefully engineered machine components all come into play. However, the user experience is a far simpler matter.

Operating a cream separator machine and maintaining it afterward is a straightforward process. Let’s consider the journey of a dairy farmer who uses a cream separator. Whether you’re a large-scale farmer or a hobbyist with a home dairy operation, the process starts with fresh, raw milk. After ensuring the milk is properly cooled, you pour it into the separator, which is where the magic happens.

How Does a Cream Separator Work?

“How does a cream separator work?” you might wonder. The machine uses the concept of differing densities between milk and cream. Once the milk is inside the separator, and the machine is turned on, it begins to spin at high speed. This rapid spinning creates a strong centrifugal force, which drives the heavier skim milk toward the edge of the bowl. Simultaneously, the lighter cream is forced to the center. From there, the separated components are directed into different outlets for collection.

The entire process is automated and requires little human intervention. The most crucial tasks for the operator are to ensure that the milk is properly introduced into the machine and to monitor the separation process. Keeping a close eye on the process helps to adjust the cream thickness if necessary. Adjustments can usually be made easily, often by turning a screw or dial on the machine.

Read the article “How Does a Milk Separator Works?” to learn more about the technical side of the cream separation process.

After you’ve successfully separated your cream and skimmed milk, you’ll find yourself with two valuable products ready for further processing or direct use. You could use the cream to make butter or ice cream, and the skimmed milk can be used for lower-fat dairy products or feeding animals.

How to Clean a Cream Separator?

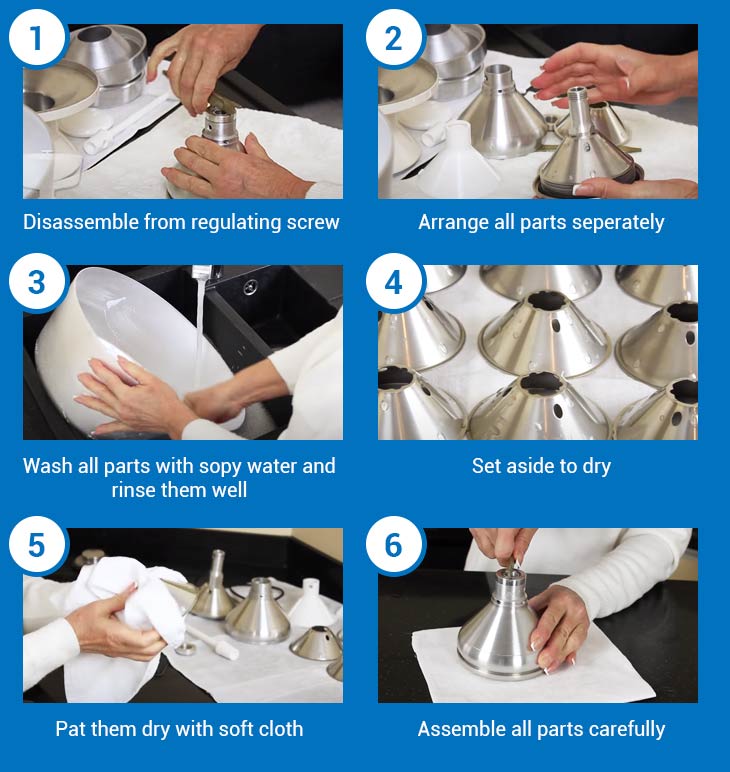

Next comes the cleaning. Cleaning a cream separator machine is a crucial step to ensure its longevity and maintain the quality of the products it produces. While the cleaning process may vary slightly depending on the specific model of the separator, the general procedure is the same.

Start by disassembling the machine. Most separators are designed to be easily taken apart for cleaning. Once disassembled, each component should be thoroughly washed. Warm soapy water is usually sufficient for this task. Pay special attention to the discs and the spouts, as they can often harbor residues. A soft brush can be handy to dislodge any stubborn particles.

After washing, rinse all components thoroughly to remove any soap residues. This step is crucial as any remaining soap can impact the flavor of your dairy products. Once the parts are thoroughly cleaned and rinsed, allow them to dry completely before reassembling. Ensuring the components are dry helps prevent the growth of bacteria and keeps the machine running smoothly.

So, there you have it! The science behind a cream separator machine might seem complicated, but in reality, operating one and cleaning it afterward is quite straightforward. With a little practice, anyone can become proficient in using this essential tool in dairy farming.

History of Cream Separators

The history of cream separation is as old as dairy farming itself, long before the advent of modern technology. In early agricultural societies, the process of separating cream from milk was a slow and laborious task. Farmers would leave fresh milk to sit in a cool place, allowing gravity to do the work. Over time, the cream, being lighter than milk, would naturally rise to the surface. While this method was effective, it was time-consuming and less than ideal for larger quantities.

The invention of the mechanical cream separator in the 19th century marked a pivotal turning point in the history of dairy farming. The first cream separator was patented by Gustaf de Laval, a Swedish engineer, in 1878. His machine was a significant departure from the traditional gravity-based method of cream separation. It used centrifugal force to quickly and efficiently separate cream from milk, significantly speeding up the process and allowing for the handling of larger quantities of milk.

This new technology was revolutionary. It made dairy farming far more productive and profitable, leading to a rapid spread of these machines across dairy farms worldwide. Early cream separators were manual, requiring the operator to turn a crank to create the centrifugal force necessary for separation.

In the late 19th and early 20th centuries, as electricity became more widely available, electric cream separators were introduced. These machines, driven by an electric motor, made the cream separation process even faster and less labor-intensive.

Over the years, cream separators have continued to evolve in response to the changing needs of the dairy industry. Modern cream separators for sale range from small, home-use models to large, industrial-scale machines capable of processing thousands of liters of milk per hour. These machines offer high efficiency, user-friendly operation, and exceptional reliability.

The cream separator has, thus, come a long way from its humble beginnings. Its evolution reflects the broader changes in agriculture and technology, playing a pivotal role in the growth and development of the dairy industry.

Types of Cream Separators

In the realm of dairy farming, cream separators come in various types, designed to cater to different needs. At a basic level, these devices can be classified into two primary categories – manual and electric cream separators. Each type offers its own advantages and is suited to different scales of operation and budgets.

Manual cream separators are the more traditional type and have been in use since the earliest days of mechanized cream separation. These machines are powered by a hand crank, which the operator turns to generate the necessary centrifugal force for separating cream from milk.

The simplicity of manual cream separators is one of their main advantages. They have fewer moving parts than their electric counterparts, which means less can go wrong. This simplicity also tends to make them more durable and longer-lasting. Maintenance is generally straightforward, usually involving regular cleaning and occasionally oiling moving parts.

Cost is another significant advantage of manual cream separators. They are typically cheaper to buy than electric models, making them an affordable choice for small-scale dairy farmers or homesteaders who are just starting out or have a limited budget.

However, manual operation does mean they require physical effort from the operator. This can be laborious, particularly when processing larger quantities of milk. Manual separators also tend to have a lower capacity and speed compared to electric models.

Electric cream separators, on the other hand, offer greater ease of use and efficiency. As the name suggests, these machines are powered by an electric motor. The operator simply has to pour the milk into the separator and switch it on – the machine does the rest.

The key advantage of electric cream separators is their speed and efficiency. They can process larger volumes of milk in less time than a manual separator, making them ideal for larger-scale dairy operations. Some high-end models can handle hundreds, even thousands, of liters of milk per hour.

Ease of use is another major benefit. Since the machine does most of the work, the operator’s physical effort is significantly reduced. This ease of use also makes it less labor-intensive to process larger quantities of milk.

Benefits of Using Cream Separators in Dairy Farming

Using cream separators bestows numerous advantages to dairy farmers. Firstly, they dramatically boost efficiency, enabling swift milk processing and optimized output. Secondly, cream separators significantly impact the quality of dairy products. By maintaining a consistent cream-to-milk ratio, these machines help produce high-quality butter and cream. Thirdly, cream separators can provide significant economic benefits.

With an array of cream separators for sale, farmers can choose a machine that aligns with their budget and scale of operations. But the benefits don’t stop there. Cream separators also allow for better waste management, as every component of milk is utilized. Furthermore, they facilitate versatility in product offerings, giving farmers a competitive edge in the market.

Additionally, cream separator machines allow farms to expand their range of dairy products. Perhaps the most common product made from cream is butter. By churning cream, the fat molecules are agglomerated into larger clusters, which eventually form a solid mass – butter. This versatile product is used widely in cooking and baking and as a spread on bread.

The cream is a primary ingredient in most ice cream recipes. The cream provides the rich, creamy texture that ice cream is known for. Depending on the type of ice cream, the cream may be used as-is, or it may be cooked into a custard first.

Sour cream is made by fermenting regular cream with certain types of lactic acid bacteria. The bacterial culture sours and thickens the cream, giving it its distinctive tangy flavor and thick texture. Sour cream is commonly used as a condiment or ingredient in various cuisines.

Cream cheese is another product made by fermenting cream, often along with milk. The fermentation process gives cream cheese its tangy flavor, while the cream provides its rich, smooth texture. It’s often used as a spread on bagels and as a key ingredient in cheesecake.

Cream is a wonderfully versatile ingredient that forms the base of many delicious and well-loved dairy products. Whether enjoyed on its own or as an ingredient in a larger recipe, the products made from cream enrich our culinary experiences.

Challenges and Solutions in Cream Separation

Cream separation, like any process, poses its own set of challenges. Regular cleaning and maintenance of a cream separator machine are necessary to maintain efficiency and precision. Furthermore, the cream separation process can vary based on the quality of milk and its fat content, adding another layer of complexity.

However, technological advancements offer a beacon of hope, addressing these challenges with increasingly advanced and user-friendly cream separators for sale. These newer models often include features such as easier cleaning and adjustable settings for different types of milk.

The Future of Cream Separator

As the dairy industry continues to evolve, so too will the technology that supports it. The future of cream separators holds promise, with innovations set to further increase efficiency, ease of use, and adaptability to different types of milk. These advancements will shape the landscape of cream separators in the USA and globally. As we move forward, expect to find more technologically advanced cream separators for sale that will make dairy farming even more efficient and productive.

Bottom Line

The importance of cream separators in dairy farming is paramount. These machines have revolutionized the industry, improving the way dairy farms operate and contributing to the high-quality dairy products we enjoy today.

At Milky Day, you can find cream separators that will satisfy your needs. From small-scale homesteaders to middle-scale dairy farmers, everyone will find the model that fits their capacity and produces the required amount of cream. With continuous advancements and a better understanding of how a cream separator works, the future of dairy farming looks promising, both in the USA and worldwide.

Explore our range of cream separators suited for home use and small to medium farms: https://milkyday.com/products/cream-separators

If you need any help in choosing the most suitable equipment for your dairy farm, you can schedule a free consultation with us! We’re always happy to assist you in making your business better.