Hey! If you question yourself about how to choose the best cream separator, then I’ll give you today 7 important pieces of facts which you should know about while choosing it. These are the issues we often hear about from our customers who write to us from all over the world. So, get ready, and let’s get started.

1. The capacity of the cream separator is not the actual amount of milk that you can process.

Sorry, didn’t want to upset you. But when the manufacturer indicates the performance of a cream separator, for example, 100 litres per hour, this does not mean that you can actually separate 100 liters of milk with this machine. The reason is that over time any cream separator becomes clogged with milk fat, particles of grass and other solid elements that might be contained in milk. Therefore, you better take into consideration that after about 45 minutes of work (time may vary depending on the quality of the milk), you’ll have to completely stop the separator, unwind the drum (top bowl) and wash it.

Need any help with choosing a cream separator of a suitable capacity? Just drop us a line and we will provide you with a free consultation! Meanwhile, explore our cream separators suited for home use and for small to medium farms: https://milkyday.com/products/cream-separators

This will take you about 15 minutes. Thus, when you choose a cream separator, keep in mind that using it with a capacity of, for example, 100 liters per hour, you can actually separate 75 liters of milk instead of 100 L, because 15 minutes will go for sure for cleaning the cream separator’s drum. Sometimes the use of milk filters can increase the separator working time between pauses.

Download our Ultimate Guide about Cream Separators. In that 10-pages PDF you will find more details about (1) how to choose the right cream separator for your needs, (2) which pitfalls you should look while choosing a supplier, (3) how to get any small cream separator to work, (4) the most frequent reasons the cream separator breaks down and how to fix it, (5) which equipment you can use with a cream separator, and (6) what you can use a cream separator for. We collected there nearly all our knowledge about cream separator we have.

2. Plastic is not always a bad thing. Or like an old Chinese proverb says, “Plastic is fantastic!”

Many people start worrying about the quality of end product, when they see that some parts of the cream separator are made of plastic. After all, plastic can easily be broken and smell not good as well. Therefore, many people prefer to buy a separator made of metal. But in fact, the effect can be quite opposite to that. After all, plastic is different and if it’s for example polycarbonate, then it’s not worth worrying about. Polycarbonate is a very durable material, which is often used even in very expensive separator models, like housing of the cream separator Milky FJ 130 ERR.

Besides, polycarbonate has a number of advantages: it is not oxidized as aluminum does and it is cheaper.Therefore, if you see two separators identical as for their capacity, but one of them is made of polycarbonate, and the other one is made of metal, while the plastic one is cheaper, then better for you to buy a plastic cream separator for sure. At least I would do so.

3. However, what sort of materials will come into contact with food?

When buying a cream separator, you should pay special attention to the parts that will come into contact with milk. As a rule, these can be the following: a milk container, a float chamber, a float, a drum and cream and skimmed milk outlets. So, the best material for all these parts is considered to be stainless steel 304.

The second place as for the quality goes for anodized aluminum. Then goes food polycarbonate and aluminum. You may ask why plain aluminum is not at the very end of the list. Well, because when it’s in contact with milk, it can be oxidized and get into milk, which is not very healthy indeed. Also, sometimes tin-plated parts are used in cream separator. We would distinguish them as the worst ever material for contact with milk, as over time, they can peel off and begin to rust.

4. What type of engine is inside?

As a rule, there are two types of engines – with or without brushes. Brushless motors are engines which have the electronics installed inside that regulate engine speed and adapts to voltage surges. Engines with brushes are simpler, because they do not have electronics inside and are equipped with carbon brushes; they can also change the speed of operation depending on changes in the voltage in the network, which can affect the quality of separation. Brushless motors are considered to be better due to that their resource is much greater than that of collectors, as the brushes of the collector engine can be worn out over time and needed to be changed. But on the other hand, motors with brushes are considered to be more safe, because they have less electronics installed inside, which can be broken down.

5.Choose the right voltage!!!

As you know, there are mainly two voltage standards worldwide: 115V and 230V. So, all you have to do is to get extremely curious and find out what standard your area uses. Otherwise, 230V connected to 115V power supply is extremely slow. 115V connected to 230V is extremely dangerous. So, if you don’t want to watch the drum (top bowl) turning with speed of 20K rpms flies your direction – choose the right voltage!!!

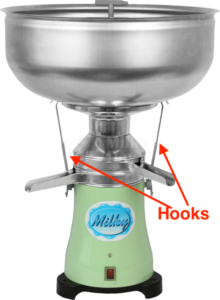

6. Is the separator fitted with fixing hooks?

Thinking of running your own farm? Then our guide to all the equipment a small farm needs will be handy for you!

Fixing crates are needed for safety as they fix the housing of the separator to the milk container. This means that if the surface the cream separator stands on does not become stable or if someone hits it by accident, the separator will not break apart and the drum rotating at a speed of 10,000 rpm does not damage the surrounding objects as well as does not injure people around. Also, if there are fixing hooks, the milk container will become more stable and will not tip over with a slight inclination of the separator.

7. What spare parts are needed to be kept in store and with which ones it is recommended to be more careful?

The sealing ring is the fastest wearing out part of the cream separator, which is installed inside the separator’s top bowl. Over time, it can harden more and more and thus it can leak the milk. Therefore, as a rule, manufacturers add one more spare ring to the separator package.

It is also recommended to be more careful with a separating disc and an adjusting screw, which is screwed into it because the thread is plastic, so the screw cannot be twisted with force, in order not to damage it. Just be very careful with this part and it will serve you for a long time.

Also you need to consider the cost of cream separator. If you have only one cow and no more than 20 litres of milk per day, there is possible to find a good and inexpensive cream separator on the market for your needs.

Well, my friend, I do hope this article was useful to you anyway. As for me, for sure, that’s a great weight off my mind. To find out which types of cream separator models are available on the Internet and what models we recommend, – you are welcome to download our Free Farm Developing Guide:

If you are looking for milk processing equipment, here you can find the right capacity of cream separator, butter churn or milk pasteurizer for your needs.

If you have any questions lease write to my personal email k.bezrukov@milkyday.com I will be glad to answer.