Short Description

- 112-gallon tank

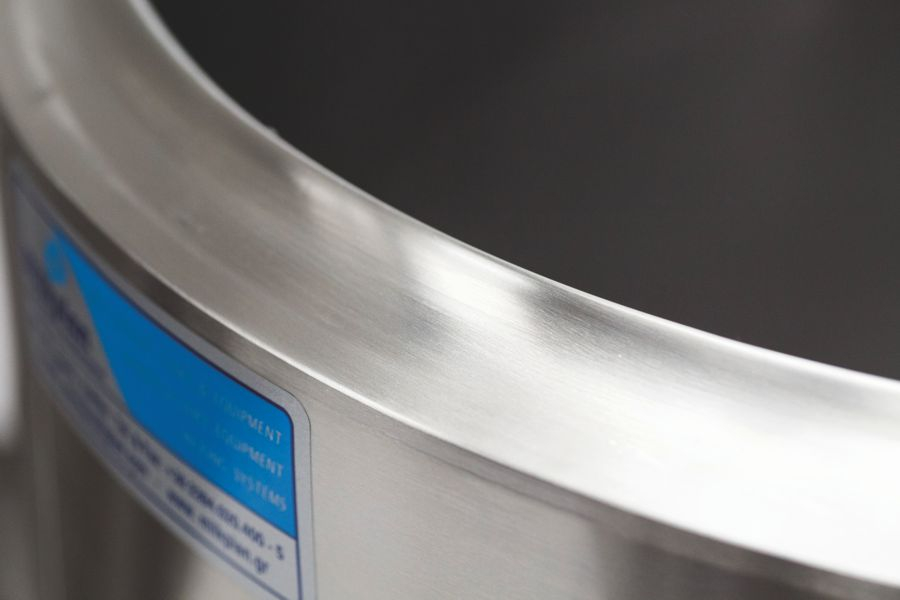

- Made of stainless steel

- Made in the EU

!Available only for the USA and Canada!

All Milkplan's MP Vertitank cooling tanks feature 90W Sirem agitation motors, rotating at 30 rpm which prevents unnecessary milk foaming.

With an integrated gravity switch, the machine automatically stops agitation when the lid is lifted, ensuring a safe and easy experience. Stainless steel springs ensure easy lifting and secure holding of the lid, while adjustable support legs guarantee precise leveling on any surface.

The cooling unit of the Cooling Tank MilkPlan MP112 is protected by perforated stainless steel covers. Due to the large size of the cooling machine, it has been designed with the cooling unit positioned behind the tank, aiming to optimize space efficiency.

To determine the milk level and calculate the amount of milk in the tank, all models of the MP Vertitank series come with a stainless steel measuring dipstick and a conversion table in liters.

Milkplan's tanks are made of food-grade materials and comply with European and US standards ISO5708 / EΝ13732 / 3A.

Strengths and weaknesses

Video

Description

We are glad to offer you the Cooling Tank Milkplan MP112 - an innovative solution for a rapid and sustainable milk cooling process.

All MP cooling tanks are made of high-quality stainless steel, which plays a significant role in the cooling process, protecting the product from acidification and the growth of pathogenic bacteria. The integrated cooling technology rapidly reduces the temperature of fresh milk from 95°F to the necessary 39-43°F, ensuring its prolonged preservation and meeting the essential cooling conditions thanks to polyurethane foam insulation that ensures minimum temperature loss.

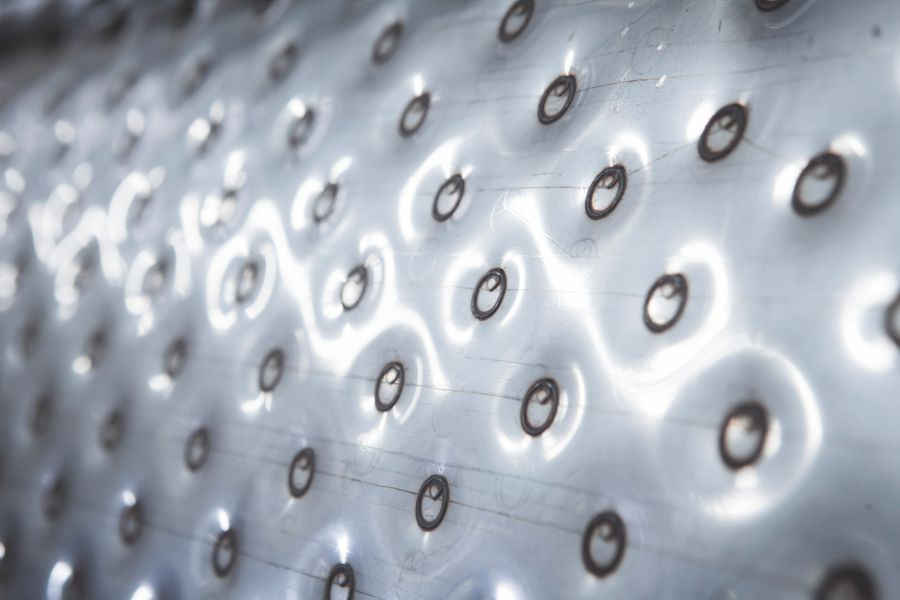

The evaporator, the smart design, and “the diamond weld pattern”, all serve to ensure direct dispersion of the milk temperature preventing the formation of frost and ice crystals, which can be a sign of unsuccessful cooling attempts. The design of the cooling tanks is carefully engineered for easy mobility, assembly, repair, cleaning, and active usage regardless of the size of the machine.

The installed cooling evaporator system and engine power are suitable for both small (cow, sheep, goat) farms and average dairy (sheep, goat) factories. Also, perfectly suitable for tropical and subtropical hot regions, where air temperature and humidity can hinder milk product handling.