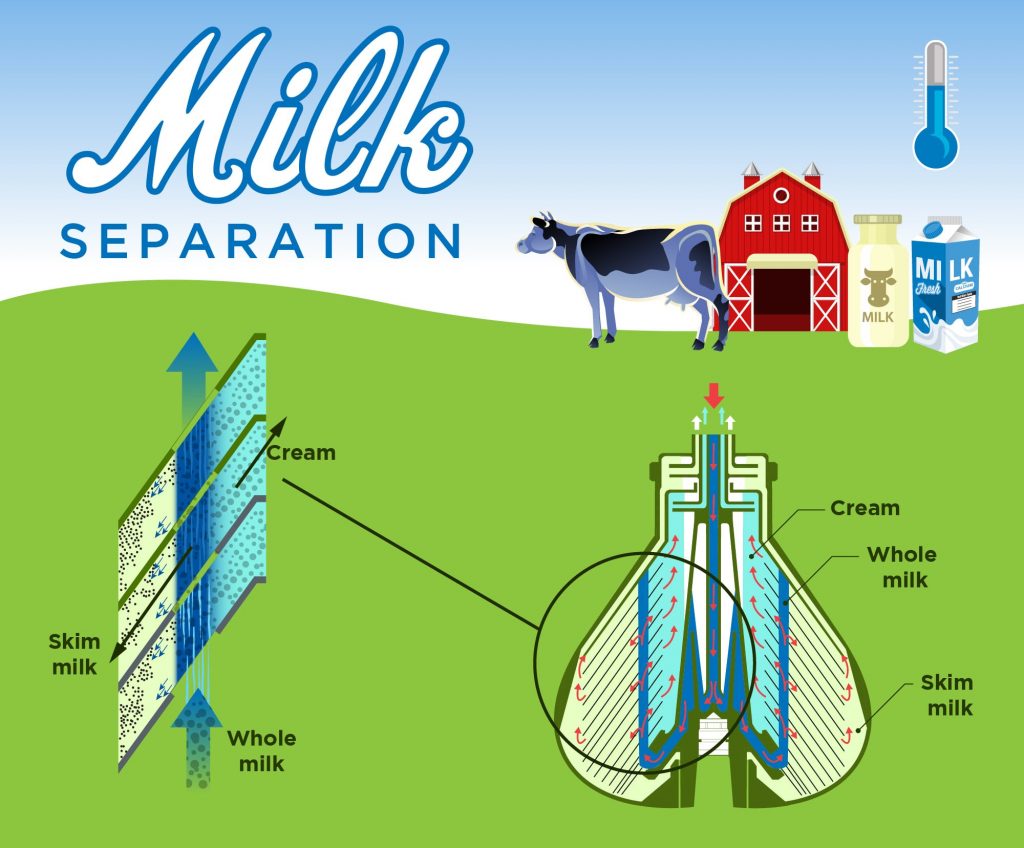

A milk or cream separator is a device that removes cream from whole milk. As a result, the whole milk is divided into cream and skim milk after separation.

Cream and skim milk have different densities and therefore they tend to get separated under the impact of gravity. You can test it yourself: Leave cow’s milk out for 24 hours and you will see how cream gathers at the top.

Source of picture: www.theprairiehomestead.com

So how does a centrifugal milk separator work?

It speeds up the milk’s separation by using centrifugal force. Separator working principle is as follows:

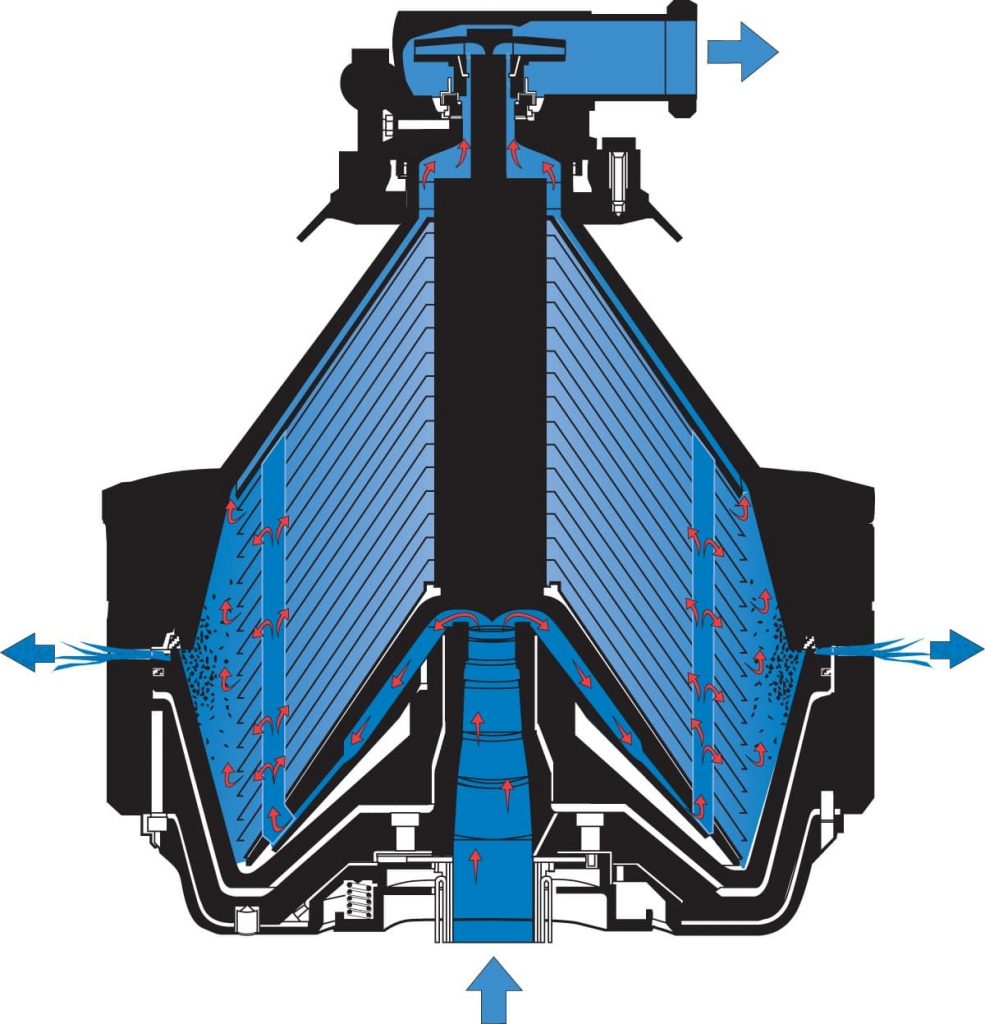

A centrifugal milk separator machine has conical discs that rotate in a bowl (drum) at a speed of 6,000 to 10,000 revolutions per minute, depending on the model.

Bowl assembly of cream separator Motor Sich

When whole milk gets inside the bowl, the centrifugal force runs it through the holes of the discs.

The milk’s fat globules go to the centre of the drum and the skim milk goes to its outer edge because it’s heavier. That is how cream extraction happens.

These machines come in different sizes so that you can get the one suitable for the volume of milk you want to work with. We offer milk separators for small to medium farms as well as home use so that you can enjoy skimmed milk and cream at home. Explore all our cream separators: https://milkyday.com/products/cream-separators

Any disk stack separator works this way. Whether it’s a small model for home use or an industrial model for a big dairy, the principle is still the same.

The next video shows how to separate cream from milk at home with the small centrifuge machine.

Main features of milk fat separator that worth to look at.

Efficiency: A high-quality centrifugal milk separator machine should leave between 0.01% and 0.05% of the butterfat in skim milk — no more than that.

Capacity: A separator’s capacity is the quantity of milk it can process within one hour.

Milk separators of different capacities

Power supply: Separators can be powered by electricity or operated by hand. Hybrid versions also exist.

Learn more about How to choose a cream separator? 7 important things if you are looking for one of them to use.

Other factors that influence milk separation

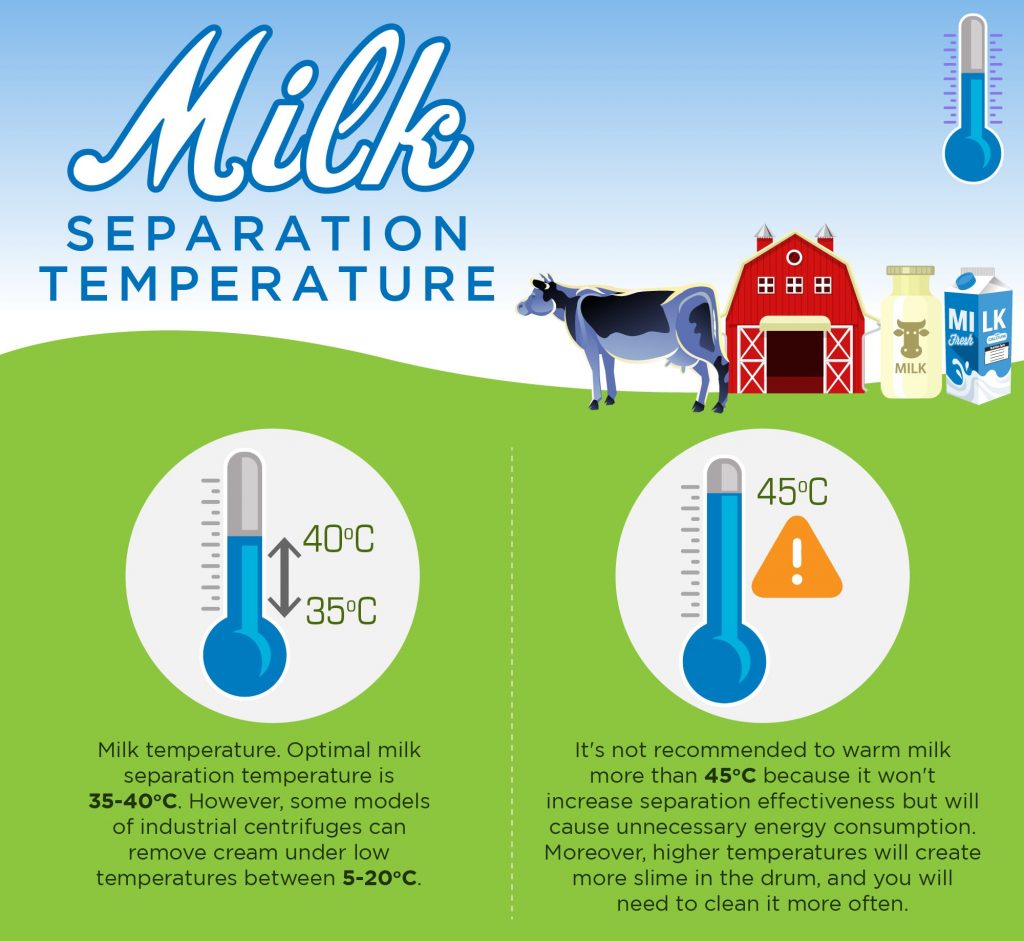

Milk temperature: The optimal milk separation temperature is 35-40 degrees Celsius. It’s not recommended to warm milk at a temperature above 45 degrees Celsius.

Amount of butterfat in the milk: More butterfat in the milk means more butterfat in the cream after separation. The maximum level of butterfat you can reach with a milk separator is about 35-40%.

Milk quality: Small separators don’t have a self-cleaning bowl like the big industrial centrifuges do. So the bowl must be cleaned manually every 30-90 minutes to remove butterfat, slime and side matter. The exact time of continuous separation depends mostly on the quality of the separated milk.

Our advice: It’s possible to use two bowls. You can alternate between them without interrupting the milk centrifugation process. While you clean one bowl, another one is working.

Factors that don’t influence milk separation

Raw vs. pasteurized: The process of making cream from raw milk doesn’t differ from the process when the milk is pasteurized.

Cow vs. goat: has a softer microstructure because of its naturally smaller fat globules (in comparison with cow milk). This is why goat’s cream rises up much slower than cow’s cream. However, both kinds of milk separate equally well with a disc bowl centrifuge.

Other useful things a milk separator can do

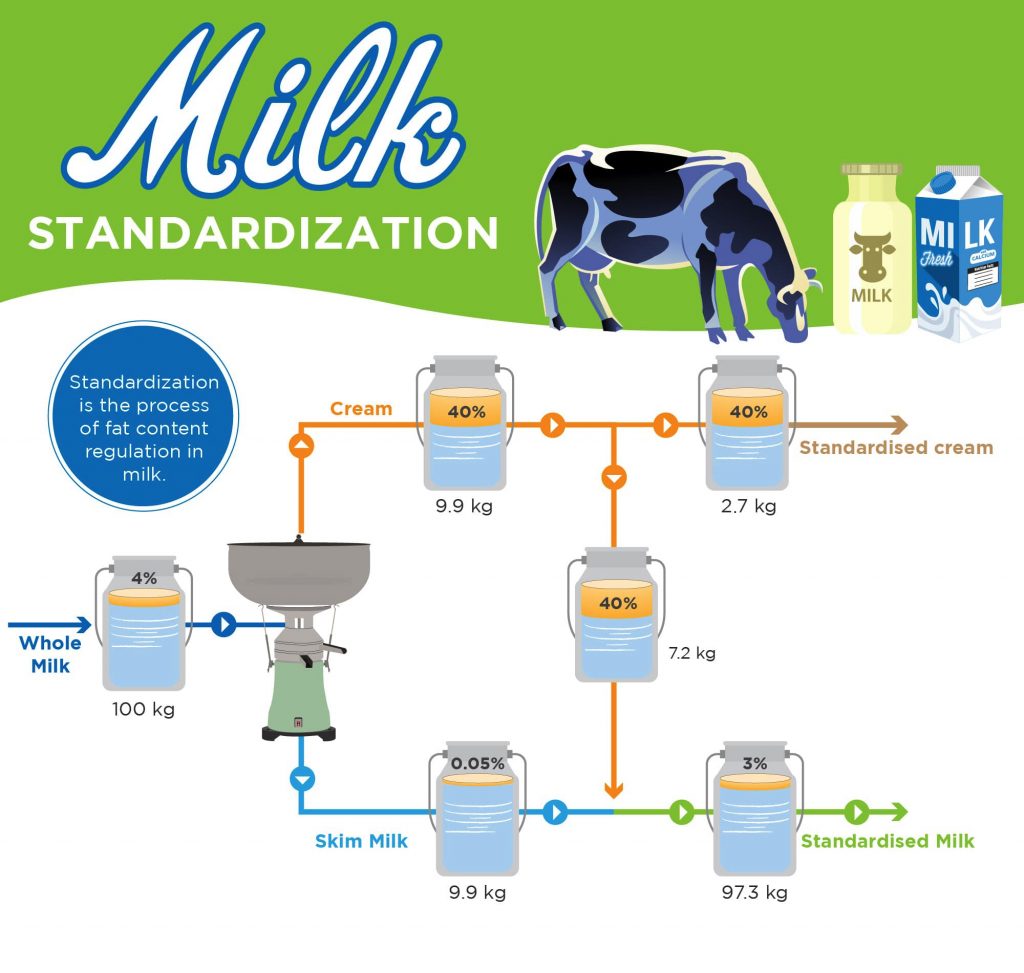

Standardize milk: Standardization is the process of fat content regulation in milk. A separator can do this.

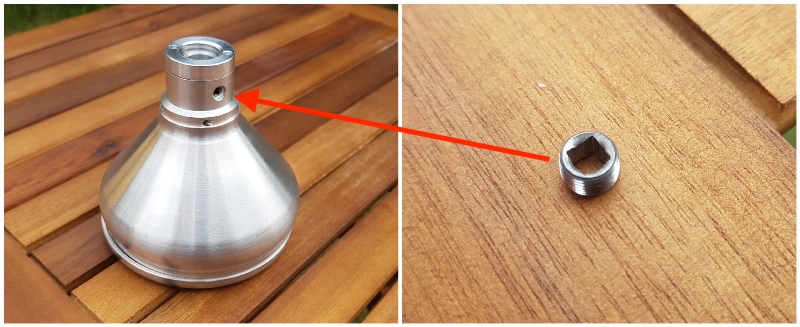

Small separators have a regulating screw in the bowl. This screw determines the fat content in the cream.

Regulating screw of milk separator Motor Sich

To get the fat content in milk standardized, users of small centrifuge machines need to return some cream to the skim milk. This practice is common in cheese making, where production requires milk with the appropriate fat content.

Large centrifuges usually have a manual or automatic standardizing system that regulates fat content instantly.

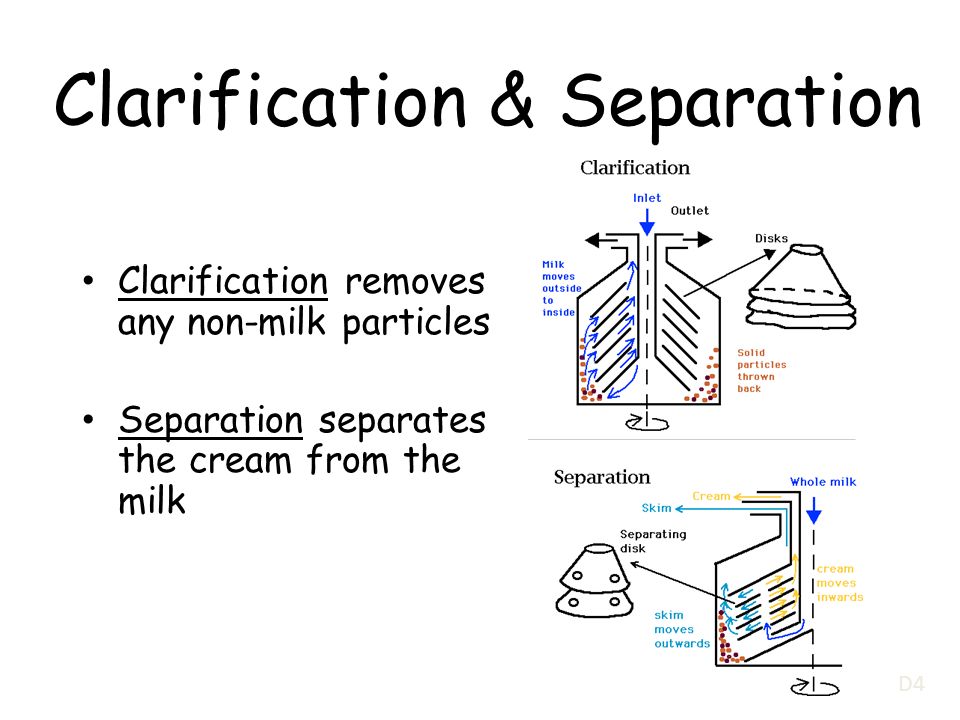

Clarify milk: Clarification is the process of removing foreign matter and dirt from milk. The clarification process is more efficient than filtration. Although centrifugal milk separators and centrifugal clarifiers are not the same machines, they operate on the same principle. That’s why there can be some dirt, grass and other matter still in the bowl after separation.

Source of picture: www.uoguelph.ca

Remove bacteria and spores from milk (industrial separators only): Heat-resistant spores and bacteria have a higher density than milk, so there are special centrifuges that remove them during the separation process, it calls bactofugation. The bacteria and spores go to the outer edge of the bowl, where they will be discharged.

Removing of bacteria with centrifugal separator. Source of picture: dairyprocessinghandbook.com

To summarize, if you are looking for a simple way to get cream for home use, a kitchen jar will be the right solution for you. But if you run a dairy and intend to separate or standardize your milk regularly — even on a micro-scale level — a centrifugal separator is what you need.

Take a look at our range of cream separators if you are in the market for one. You will find many high-quality and time-tested models.

With love,

Milky Day

Experts in small cream separators, butter churns and milk pasteurizers